Project development description:

STEP 1: the client comunicates the main characteristics of the cylinder required.

STEP 2: the technical sales department assists the customer in defining technical specifications of which : dimensions , functionality , cyclicality, fluid requirement and type of application. In this step eventual critical points will be assesed and discussed.

All specifications and data is subsequently sent to our technical office.

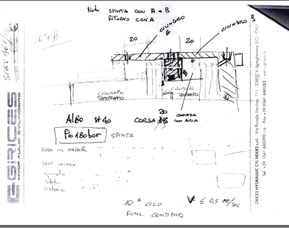

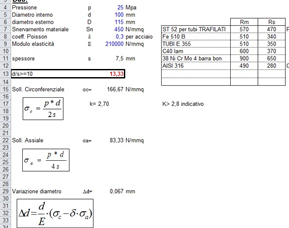

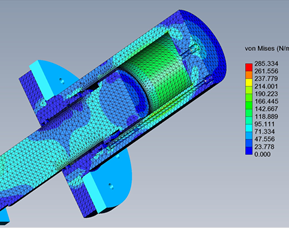

STEP 3: based on the specifications and data collected in the previous development phase the technical department begins the project.

The dimensions , the components and type of material are defined

based on the calculations using GSC (Grices Safety Coefficient) or for particular applications FEM (Finite Element Method) is used.

STEP 4: the technical department defines the seals used, for the application considering hydraulic fluids, speed, frequency and operating temperature granting high standards of quality, reliability and enduring product performance.

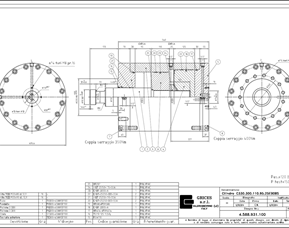

STEP 5: the technical department provides the customer with a preliminary assembly design which includes a detailed list of components and seals.

STEP 6: customer approval of the preliminary assembly design before proceding to final design.

STEP 7: the technical department proceedes to the final design stage which includes all the constructive designs and detailed list of components and seals.

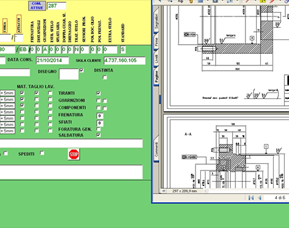

STEP 8: all data and specifications , components , product quantity , delivery date , CNC programs , assembly and construction drawings, are inserted into CPDS (Cylinder Production Data System) that allows us to monitor the production at every workstation in each phase granting complete traceability of the order.